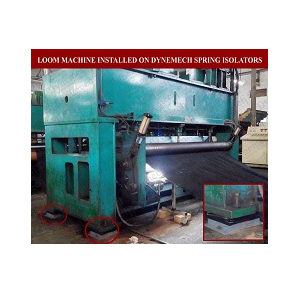

In Textile Manufacturing, as in many other industrial fields, production speed is a decisive factor. But high production speed often means vibration problems due to rotating rolls and other machinery parts. Vibrations not only put at risk the productivity and the operation time. Mechanical averages caused by vibrations can lead to great loss of investments.

Most spinning is done using break or open-end spinning, this is a technique where the staples are blown by air into a rotating drum, where they attach themselves to the tail of formed yarn that is continually being drawn out of the chamber. The spinning machine takes the roving, thins it and twists it, creating yarn which it winds onto a bobbin. Plying is done by pulling yarn from two or more bobbins and twisting it together, in the opposite direction from that in which it was spun.

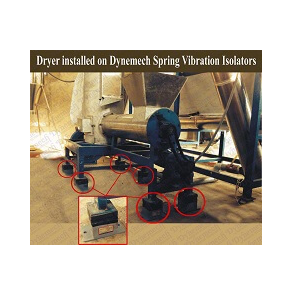

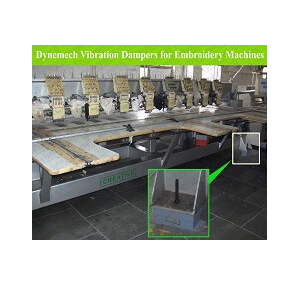

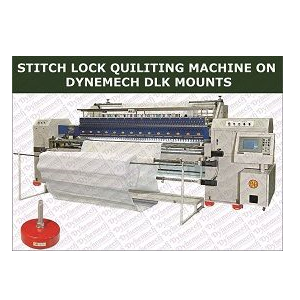

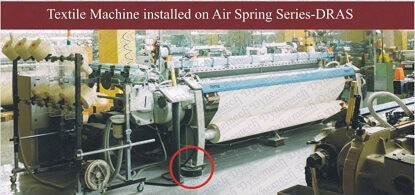

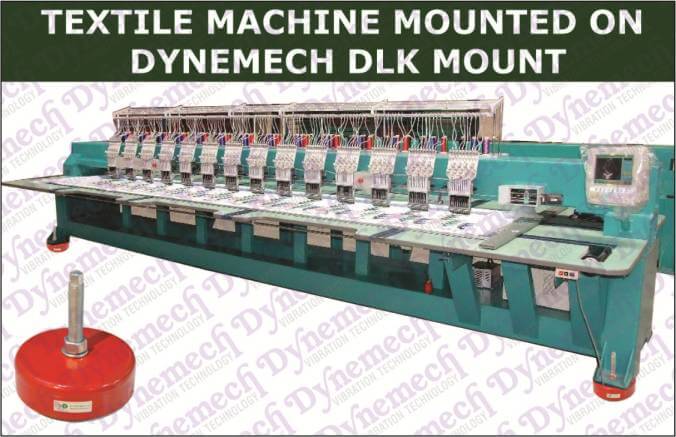

Dynemech Systems are experts in vibration reduction for fast rotating systems since many years. Different well-proven concepts are available to realize customized and high efficient solutions against vibrations in most textile manufacturing applications. Well proven and tested solutions from Dynemech are successful in reducing rotating/spinning vibration considerably.

Dynemech is the leading supplier of Anti Vibration Mounts to all kinds of CNC machine manufacturers in India and abroad. Dynemech's vibration damping products are being exported extensively to Europe, South Korea, Australia and the United States. Dynemech's engineering team provides complete guidance in proper pad selection for various different CNC machines depending on the machine specifications and external factors. They provide detailed installation notes with illustrative diagrams for correct anti vibration mount installation.