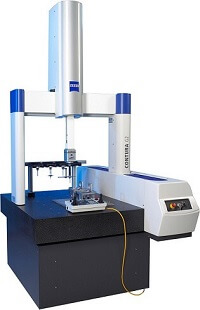

CMMs have traditionally performed the quality assurance function in labs and gage rooms off of, or away from, the production floor. Today, however, we are hearing much more discussion about putting CMMs into the factory environment. The measuring speed and accuracy of Coordinate Measuring Machines (CMM’s) are improving every year. Newer CMM’s are being designed and built which should function with repeatability right on the production floor.

Machining, stamping and other operations produce plenty of vibration, and those processes should be floor-isolated. Still, energy can find its way into the CMM as a source of errors, so some type of vibration isolation is needed. The production floor may have presses or hammers near the CMM, which produce massive vibrations and can lead to grossly inaccurate readings on the CMM. Vibration is one environmental factor which can compromise a CMM’s accuracy and repeatability. Without compromising accuracy, CMM manufacturers provide their users with the maximum levels of vibration which their machines are capable of withstanding. Ideally, if all components of a CMM, including the part to be measured, were to vibrate in unison at a specific frequency, amplitude, phase and orientation, no degradation in measured performance would result.

When isolation is required, it is typically low frequency (less than 25 Hz) vibration that requires attenuation. Dynemech Systems has over 20 years experience in vibration isolation. They are specialists in

CMMs, Dynamometers, Electron Microscopes, Metrology Equipment. Dynemech’s pneumatic isolators Series DRAS and Series DLPM provide significant vibration isolation for metrology equipment requiring low frequency vibration control.Series DRAS are ideal for low-cost metrology equipment where there is no sudden loading across the table. Series DLPM are auto-leveling pneumatic isolators which can sense the load placed on the table and automatically level the table surface. Both these models are highly suitable for low frequency vibration damping.

Additionally, in case there is excessive vibration, Dynemech can also provide complete turnkey solution for the construction for an Isolated Foundation. We will provide complete engineering drawings and specifications with installation procedures. Installation supervision at the site can be handled by our team of expert engineers.

Dynemech is the leading supplier of Anti Vibration Mounts to all kinds of CNC machine manufacturers in India and abroad. Dynemech's vibration damping products are being exported extensively to Europe, South Korea, Australia and the United States. Dynemech's engineering team provides complete guidance in proper pad selection for various different CNC machines depending on the machine specifications and external factors. They provide detailed installation notes with illustrative diagrams for correct anti vibration mount installation.