Electrical Discharge Machining, EDM is one of the most accurate manufacturing processes available for creating complex or simple shapes and geometries within parts and assemblies. EDM works by eroding material in the path of electrical discharges that form an arc between an electrode tool and the work piece. EDM manufacturing is quite affordable and a very desirable manufacturing process when low counts or high accuracy is required.

To obtain a specific geometry, the EDM tool is guided along the desired path very close to the work; ideally it should not touch the workpiece, although in reality this may happen due to the performance of the specific motion control in use. In this way, a large number of current discharges (colloquially also called sparks) happen, each contributing to the removal of material from both tool and workpiece, where small craters are formed. The size of the craters is a function of the technological parameters set for the specific job at hand. They can be with typical dimensions ranging from the nanoscale (in micro-EDM operations) to some hundreds of micrometers

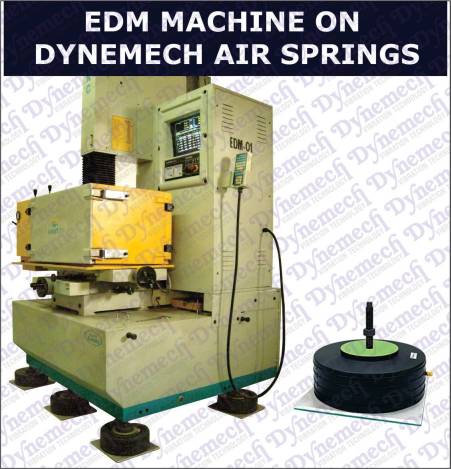

in roughing conditions. For such highly accurate machines, proper levelling and external vibration isolation is of utmost priority. Dynemech’s Anti Vibration Mounts provide both these levelling and vibration damping properties. The Anti Vibration Mounts are also very simple to install and easy & convenient to order. Anti Vibration mounts remove the need to make any kind of foundation for the machine, thus making maintenance and movement of the machine a trivial affair. The tool life of the electrode is greatly improved because of enhanced vibration control of the machine placed on Dynemech’s Anti Vibration Mounts. Even external factors like press or hammer vibrations can be effectively controlled using Dynemech’s Anti Vibration Mounts. EDM machine can be installed on Dynemech’s Ultra sensitive Air Springs or Screw Support Mounts with dual layer Dp insulation plates for maximizing the external vibration isolation.

Dynemech is the leading supplier of Anti Vibration Mounts to large number of EDM machine manufacturers and end-users in India and abroad. Dynemech’s vibration damping products are being exported extensively to Europe, South Korea, Australia and the United States. Dynemech’s engineering team provides complete guidance in proper pad selection for various different CNC machines depending on the machine specifications and external factors. They provide detailed installation notes with illustrative diagrams for correct anti vibration mount installation.

Dynemech is the leading supplier of Anti Vibration Mounts to large number of EDM machine manufacturers and end-users in India and abroad. Dynemech's vibration damping products are being exported extensively to Europe, South Korea, Australia and the United States. Dynemech's engineering team provides complete guidance in proper pad selection for various different CNC machines depending on the machine specifications and external factors. They provide detailed installation notes with illustrative diagrams for correct anti vibration mount installation