Effective Installation of CNC Machines

October 1,2018 12:17 pm | Posted in Anti-Vibration Mounts

CNC Machine installation in any machine shop entails a significant capital investment. Thus, proper installation is essential for consistent and reliable performance of the machine tool.

The CNC Manufacturer’s recommend that the CNC machine should be installed on a flat surface so that the machine does not rock or slide during operation. Improper installation and an unleavened machine have known to cause both numerical error and loss of precision during the machining operation. Machinery Installation Engineer’s advise the workbench be located in a vibration-free area with a floor that is designed to support the full weight of the work bench, machine, toolings and accessories, and working materials. While installing the machine tool, the foundation should be firm ,leveled and stable in order to maintain the machining accuracy of the machine.

But, space constraints, costlier shop floors, condition of soil stratum besides practical considerations don’t necessarily allow this. New CNC machine tools have to be installed besides other production and quality control equipments on the same shop floor. It results in vibration transmission problem for both the CNC Machines and the other vibration-sensitive machines installed on the same shopfloor.

Now a days, both passive vibration controls and active vibration controls need to be put into place to ensure vibration free operation of CNC machines. However, depending upon the condition of soil stratum supporting the shopfloor, general counter measures for the foundation of the machine tool may also need to be taken.

Moreover, accurate leveling of the machine is necessary for coolant and oil drainage. Precise levelling ensures the correct angle geometry of the machine’s X, Y, and Z axes. Many other factors impeding a machine’s ability to remain level — the rigidity of the floor, the stability of the support under the floor, vehicular traffic passing nearby, construction activity nearby, seismic activity, and so on can be tackled by installing machines on levelling elements.

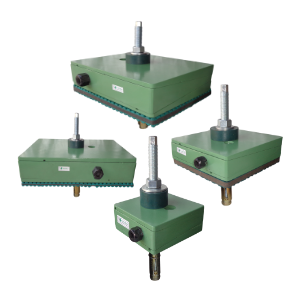

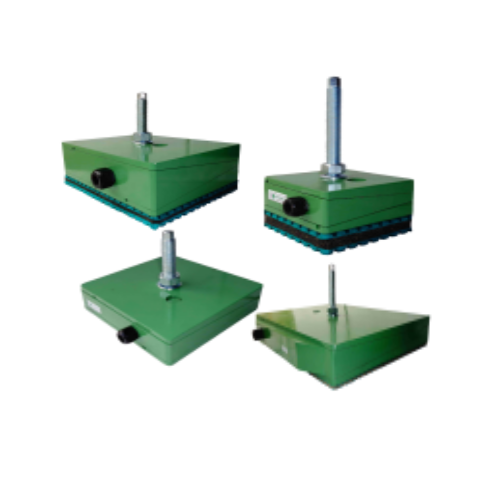

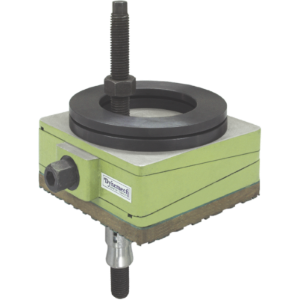

Dynemech provides tried and verified solutions for Modern Precision Machinery Mounting Systems.

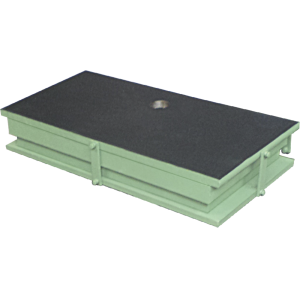

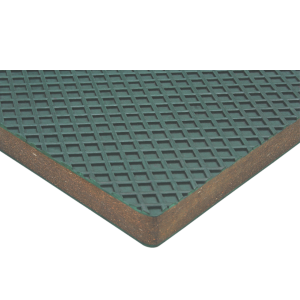

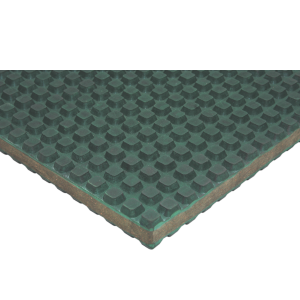

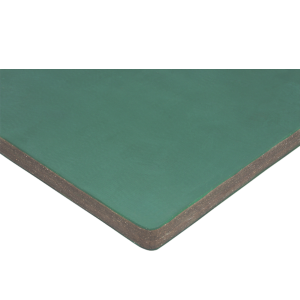

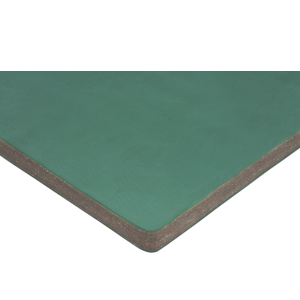

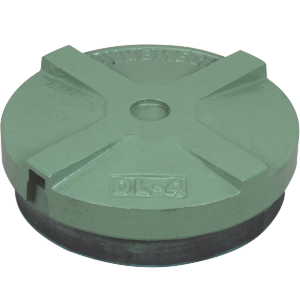

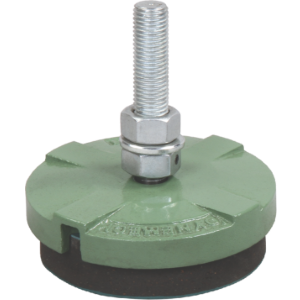

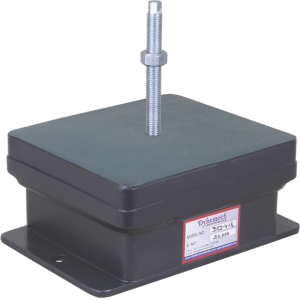

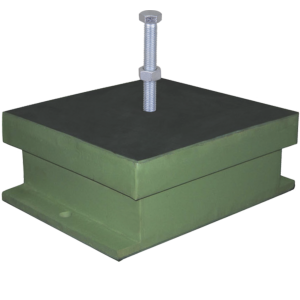

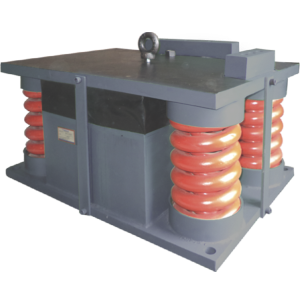

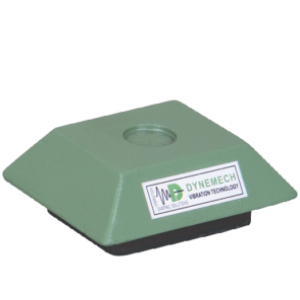

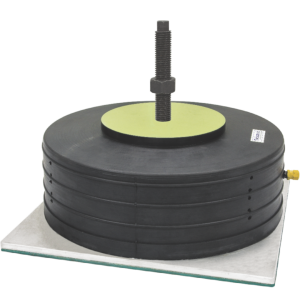

Our vibration damping solutions range from rectangular Wedge Mounts, Circular Damping Mountings to Leveling Elements, Viscous and non-viscous High Deflection Spring Isolators,

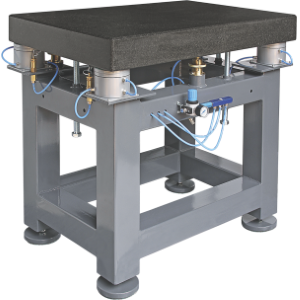

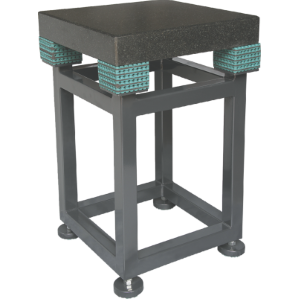

Low Frequency Pneumatic Vibration Isolators, Vibration Isolated Tables and Foundation Isolation. Isolated foundation is required for active vibration damping for power presses, forging hammers, engine test rigs, and passive vibration isolation of machining centers, grinding machines, measuring & testing equipment, laser cutters and microscopes.

- Install CNC on a clean, flat surface.

- Installation to be done on a vibration free , strong floor.

- Machine tool foundation should be strong and firm.

- For accurate leveling, precision machine levelers can be used – with or without anti vibration damping.

- Depending on the soil condition, anti vibration pads or foundation isolation needs to be considered.

More links for TPM SERIES MOUNTS

TPM SERIES MOUNTS

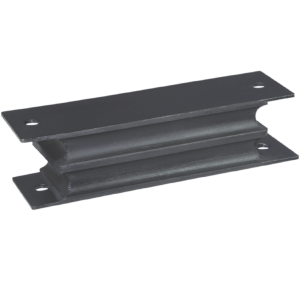

TPM Series Mounts – Series DFP

TPM Series Mounts – Series DBP (Bolt On)

TPM Series Mounts – Series DTP (Bolt Through)

TPM Series Mounts Series DRC

TPM Series Mounts Series DR