Foundation Isolation – Zeiss CMM

Machine Details:

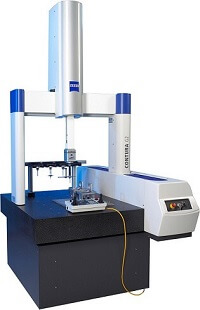

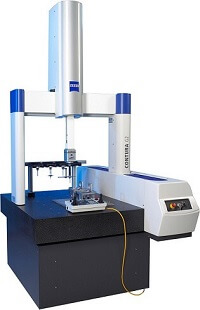

- Isolated foundation for Carl ZEISS CMM make contura G2

- X/Y/Z measuring – 700/1000/600 mm

- Machine Weight: 1550 Kg.

Dynemech Foundation Isolation Calculations:

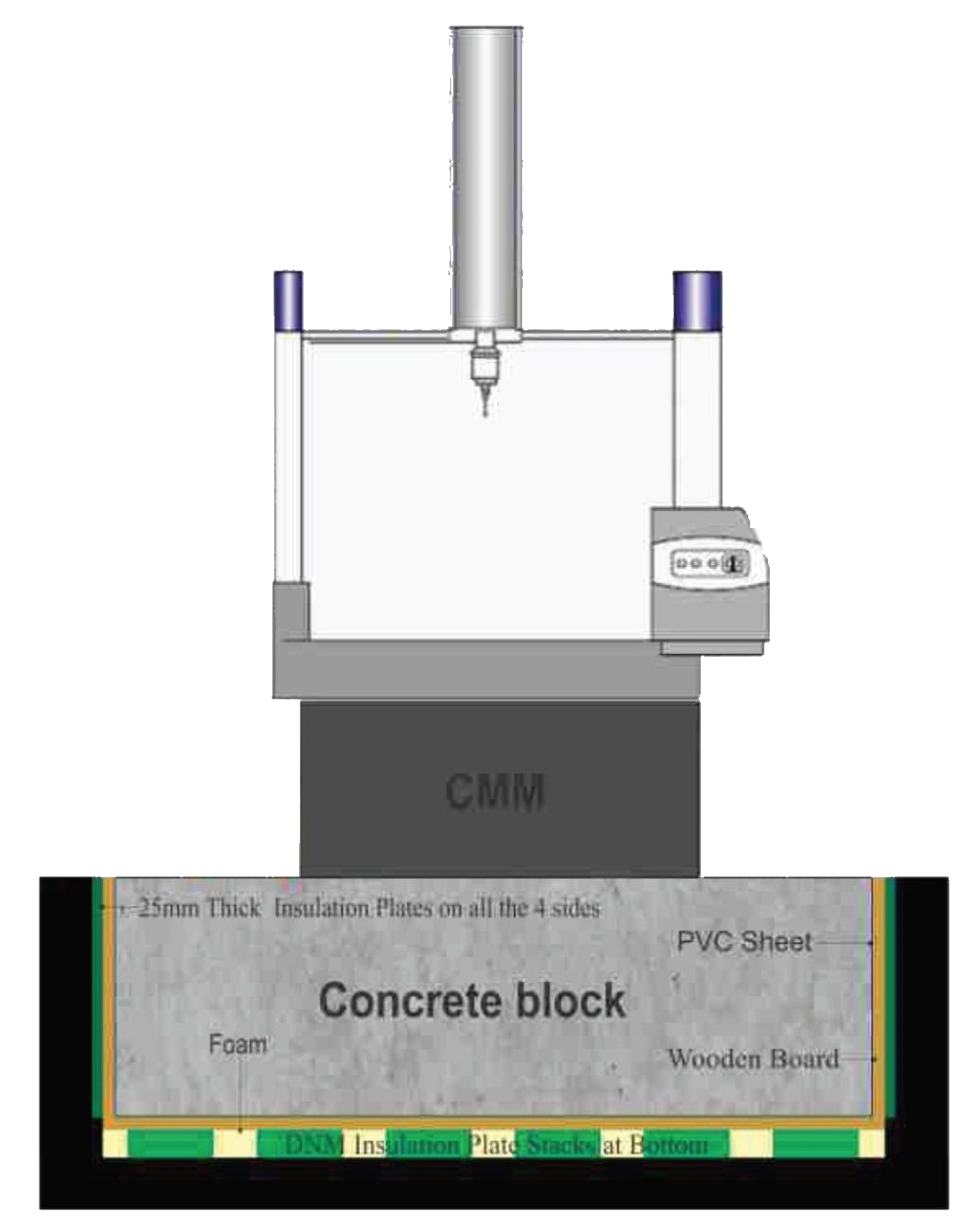

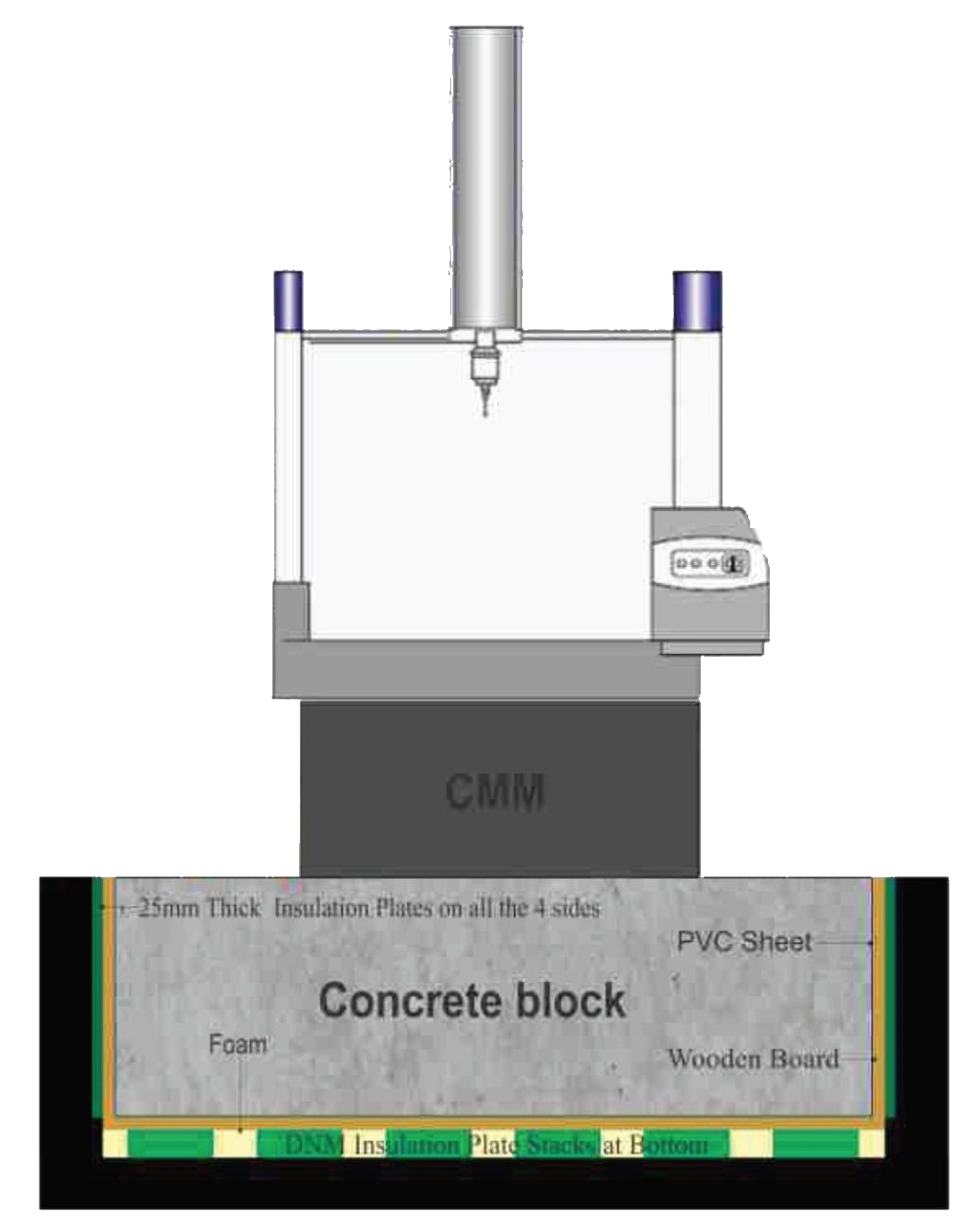

- Size of concrete block : 1900mm x 2200mm x 1000mm.

- Total weight of Machine & Concrete Bloc : 12000Kgs.

- Foundation Pit Size : 2100mm x 2400mm x 1100mm.

- Foundation Isolation Solution : Dynemech’s Foundation Insulation Sheet – 75mm thick.

Fig: Zeiss Contura G2 CMM

Fig: Zeiss Contura G2 CMM

Foundation Isolation Solution provided by Dynemech

Fig: Zeiss Contura G2 CMM

Fig: Zeiss Contura G2 CMM

Guidelines :

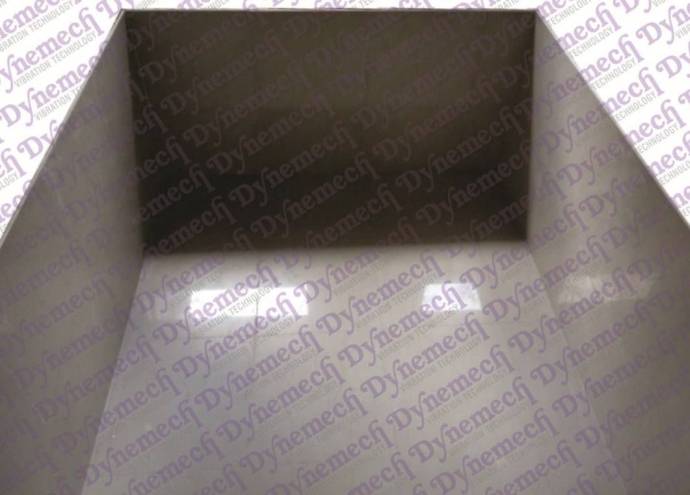

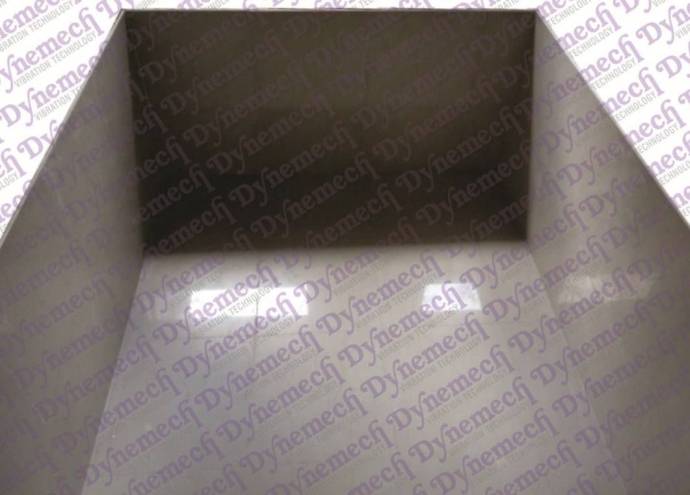

- Make a pit as per the recommended size - 2100 x 2400 x 1100 mm.

- Pit should be 100% water proof; check ground water conditions.

- The inner surface of the pit should be clean, dry & smooth.

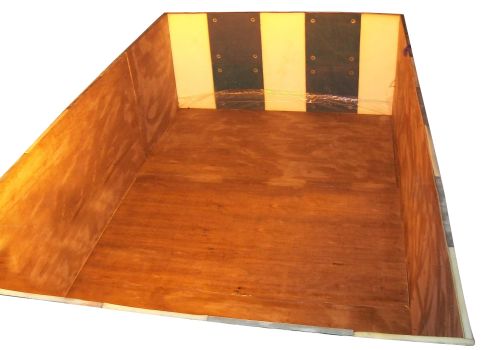

Fig: Pit Construction

Fig: Pit Construction

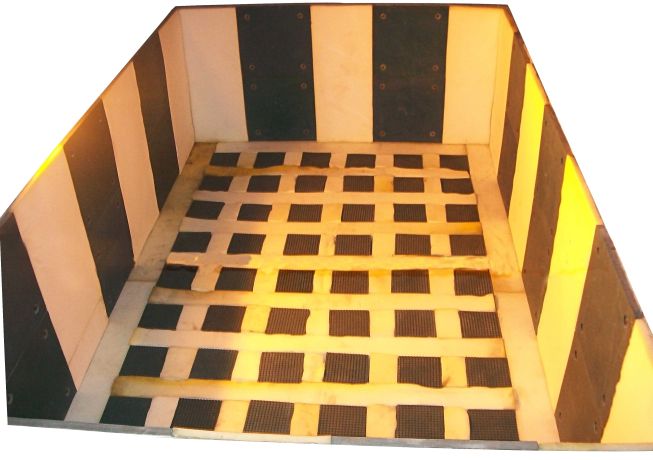

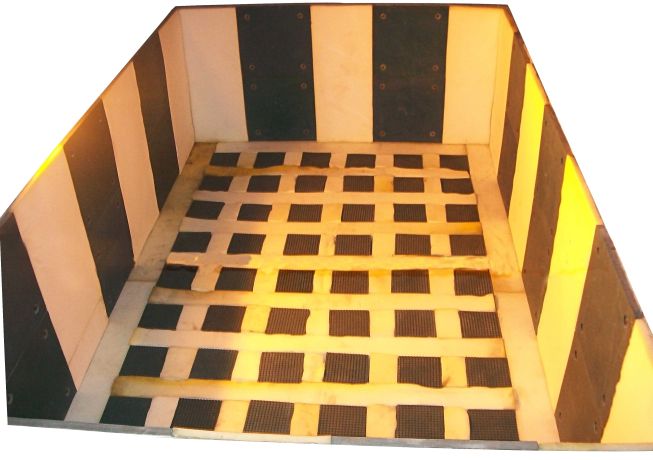

Fig: Pit after placing Dynemech Insulation Sheet and Filler Foam.

Fig: Pit after placing Dynemech Insulation Sheet and Filler Foam.

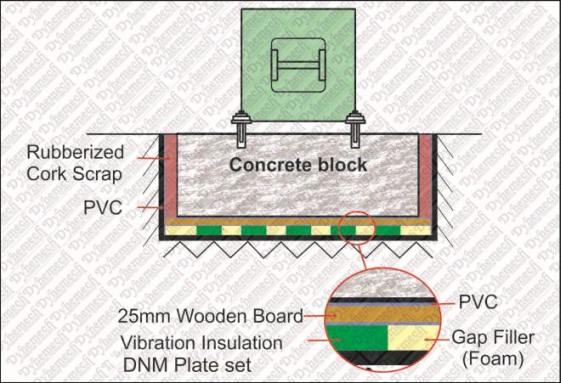

- . As per the detailed layout supplied by Dynemech, place vibration damping plate set DNM Paste them to the pit base using - Pidlite SR-505 adhesive.

- Place filler foam in the gaps between the Insulation plate set DNM. Paste them to the pit surface.

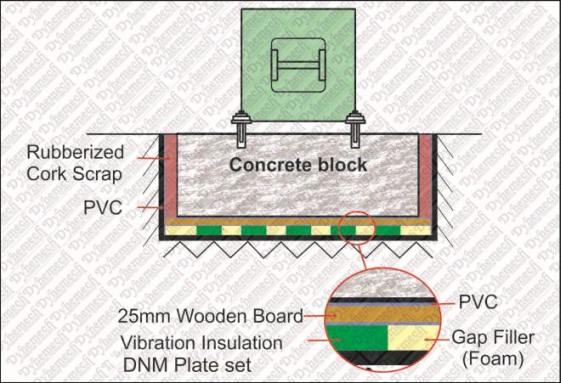

- In some special cases of Isolated foundation, the sides of the foundation wall are also covered with layers of our insulation sheet to prevent foundation shaking. The horizontal vibrations traveling through the foundation are fully absorbed using these insulation sheets on the side-walls.

Fig: Pit after placing Dynemech Insulation Sheet and Filler Foam.

Fig: Pit after placing Dynemech Insulation Sheet and Filler Foam.

Fig: Dynemech Insulation Sheets on Side walls for preventing horizontal vibrations

Fig: Dynemech Insulation Sheets on Side walls for preventing horizontal vibrations

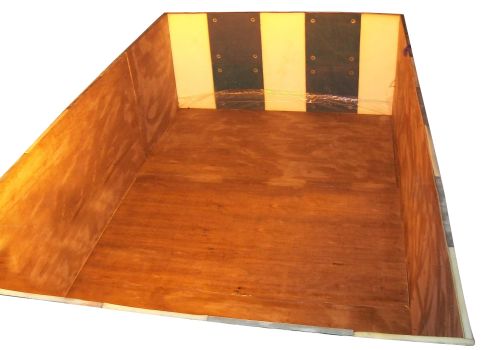

- Place PVC on the entire pit surface and side walls. Seal the overlapping joints of the PVC sheet with adhesive tape so that the concrete water should not leak in to the pit base.

- Place 25mm thick wooden board layer and joint should be sealed with adhesive tape. This will act as a support for the initial concrete pour.

- Place another layer of PVC sheet on the pit base and the side walls joints sealed with adhesive tape.

- Place another layer of PVC sheet on the pit base and the side walls joints sealed with adhesive tape.

- Pour concrete up to a depth of 150mm and allow it to dry, this will act as a compression plate. After drying the compression plate erect reinforcement and pour concrete in the rest of the concrete block volume. Concrete should be poured in layers of 300mm+300mm+350mm to complete a depth of 1100mm, allow each layer to dry and pour another layer.

Fig: Layer of PVC sheet on the pit base and the side walls

Fig: Layer of PVC sheet on the pit base and the side walls

Fig: Joints sealed with adhesive tape

Fig: Joints sealed with adhesive tape

Fig: Pit after covering Insulation Sheets with Wooden Board and PVC sheets.

Fig: Pit after covering Insulation Sheets with Wooden Board and PVC sheets.

- The concrete block and the pit tub should not come in contact with each other.

- Care should be taken that the concrete or concrete laced water should not leak in to the insulation plate area.

- In case the side walls are not isolated using Dynemech insulation sheets, the side gaps may be filled with rubberized cork scrap.

Fig: Dynemech Isolated Foundation Solution

Fig: Dynemech Isolated Foundation Solution