AVMs for Honing Machinery

Anti Vibration Pads For Honing Machinery

VIBRATIONS affect PRODUCTION

- Numerous mechanical structure, rotating and revolving parts with different mechanisms working in compression, stress and torsion in a machine – lead to vibrations.

- Vibration would make the size or surface roughness of proposed part poor, leading to rejections.

- Vibrations may also travel from external environment to Honing Machines disturbing surface finish and accuracy of the job.

DYNEMECH VIBRATION REDUCTION MOUNTS

- Dynemech low natural frequency isolators damps most of the incoming vibrations and allows smooth operation.

- Separate the dynamical system (generating vibratory frequencies and shocks) from its environment.

- By creating a phase difference of vibration frequency, both passive and vibration control can be achieved in honing applications.

- Mounts constructed from high strength material and quality production processes

- Enhanced and consistent component finish, accuracy and part tolerances

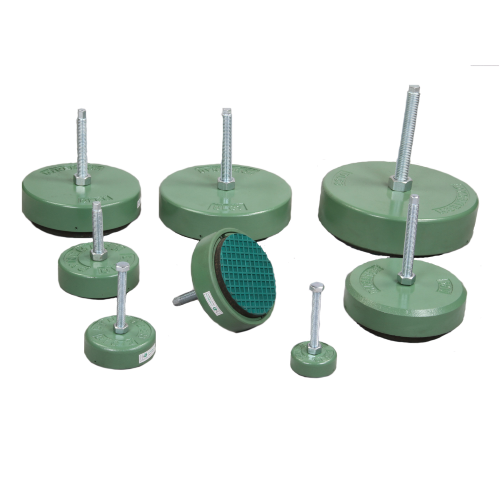

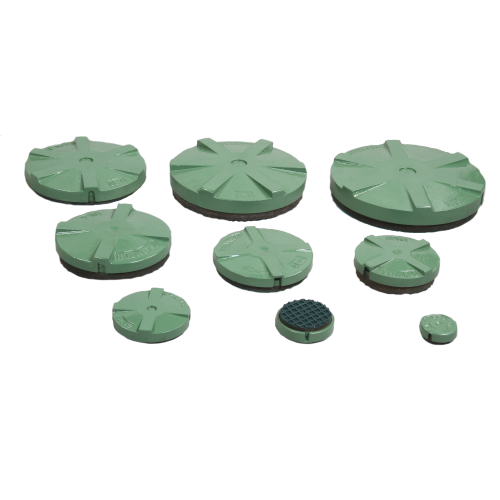

Screw Support Mounts

Screw Support Mounts

Series DLC

Screw Support Mounts

Screw Support Mounts

Series DLK

Screw Support Mounts

Screw Support Mounts

Series DL

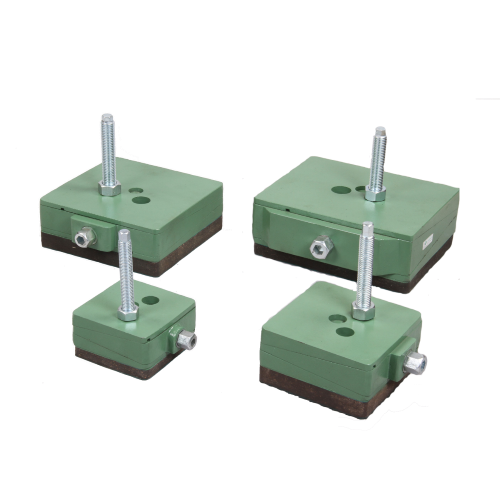

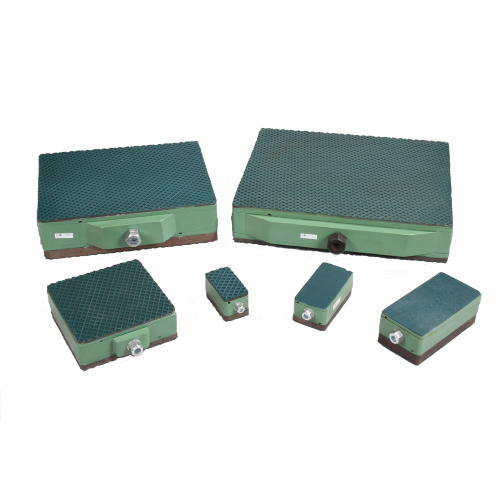

Wedge Mount

Wedge Mount

Series DB

Wedge Mount

Wedge Mount

Series DT

Wedge Mount

Wedge Mount

Series DF

Honing Machine Applications

Fig: Dynemech Anti Vibration Mounts for Honing Machine Vibration Control

Fig: Dynemech Anti Vibration Mounts for Honing Machine Vibration Control

Fig: Dynemech Anti Vibration Mounts for Honing Machine Vibration Control

Fig: Dynemech Anti Vibration Mounts for Honing Machine Vibration Control

Fig: Vibration and Leveling of Honing Machines mounted on DYNEMECH's AntiVibration Mounts

Fig: Vibration and Leveling of Honing Machines mounted on DYNEMECH's AntiVibration Mounts

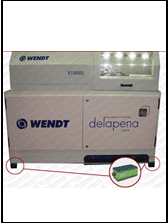

Fig :Delapena Wendt On Honing Machine

Fig :Delapena Wendt On Honing Machine