Injection Moulding Anti Vibration Mounts

Installation of injection moulding systems on Dynemech Vibration Dampers is preferable to avoid the resonance phenomenon due to the various excitation frequencies and also absorb the shock of the moulding process.

Unlike other competitive anti vibration pads, where machines shakes when the die closes, Dynemech insulation plates provide increased stability and vibration reduction simultaneously on die closing/opening.

View on Youtube

Dynemech Injection Moulding Machine Mounts with Elastomeric Pads offer many benefits:

- Increased equipment life.

- Installation Savings – Machines are installed faster and easier.

- Simplified machine installation.

- Precision Leveling and alignment of machine mounts reduces machine wear and tear & increases tool life.

- Machine “walking” prevented.

- Different products/customized solutions available.

- Reduced shock and vibration.

- Simple integration into the production plant due to flexible installation.

- Elimination of anchor bolts. Machine can be easily re-located and Re-Levelling is much faster and easier.

- Better Structural Safety.

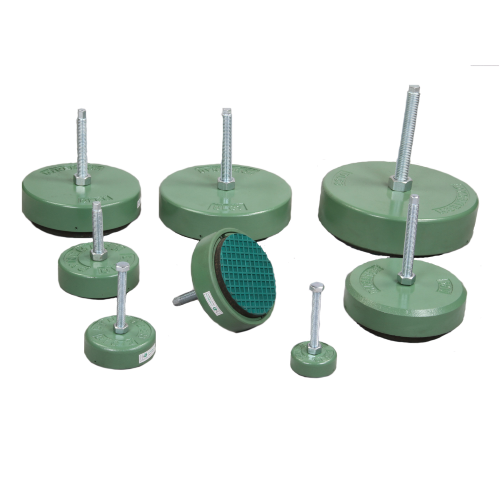

Screw Support Mounts

Screw Support Mounts

Series DLC

Screw Support Mounts

Screw Support Mounts

Series DLT

Screw Support Mounts

Screw Support Mounts

Series DLK

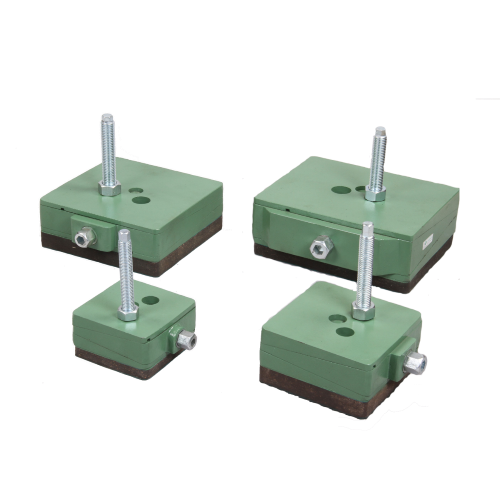

Wedge Mount

Wedge Mount

Series DB

Wedge Mount

Wedge Mount

Series DF

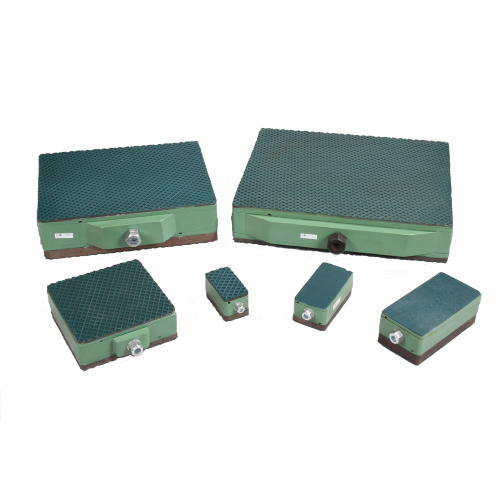

TPM Series Mounts

TPM Series Mounts

Series DTP

Precision Leveling Mounts

Precision Leveling Mounts

Series VHS

Applications Of Injection Moulding Machine Mounts

Fig :Injection Moulding Machine Installed on Dynemech Wedge Mounts

Fig :Injection Moulding Machine Installed on Dynemech Wedge Mounts

Fig :Precise Leveling Mounts for Injection Moulding Machines

Fig :Precise Leveling Mounts for Injection Moulding Machines

Fig :Injection Moulding on Precision Leveling Wedges

Fig :Injection Moulding on Precision Leveling Wedges

Fig :Injection Moulding Machine Installed on Dynemech Wedge Mounts

Fig :Injection Moulding Machine Installed on Dynemech Wedge Mounts

Fig :DLK Leveling and Machine Mounts for Injection Moulding Machines

Fig :DLK Leveling and Machine Mounts for Injection Moulding Machines

Fig :Injection Molding Height Raiser Anti Vibration Mounts

Fig :Injection Molding Height Raiser Anti Vibration Mounts